Product Description

Introduction

The small but powerful fasteners play a vital role in various industries including automotive, aerospace and construction. "dome head blind rivet"—we'll gain insight into their exceptional strength and versatility that make them indispensable in so many applications.

| 5050 Aluminum blind rivets |

|

| Material | 5050 aluminum/ steel mandrel |

| Head type | dome head |

| Diameter | 3.2mm/3.9mm/4.8mm(1/8" 5/32" 3/16") |

| Length | 6.5mm--25mm(1/4"--1") |

Applications

Construction, shipbuilding, machinery, automobile manufacture, household and so on

Advantages

High quality aluminum blind rivets advantages

1. Low installation cost.

2. Tamper proof.

3. Vibration resistance.

4. Reliable.

5. Where there is no access to opposite side of work.

6. Simple to Install.

7. Wide variety of head styles and length.

8. No need for tapping in the hole.

9. Strong and low cost fastener.

10. Ideal for wide range of applications.

Packing details

1. 25kgs/ carton, then in pallet,

2. 1000 or 500 pcs/ box, 10 boxes/ carton, without pallets,

3. 1000 or 500 pcs/ box, 6 boxes/ carton, with pallets

All packing can be done as per customer!

What is Blind rivets?

Blind rivets are high strength one piece break-stem fastener that require access from one side only. They are available in various materials such as aluminum alloy, steel and stainless steel in a variety of lengths & diameters. Also they are available in various head forms - dome head, countersunk and large flange to suite applications where wide load spread or flush surface is required.

A general purpose rivet that can be used where the materials to be fastened does not require load bearings. Open-end blind rivets provide an economical means for fastening metal parts where easy disassembly is not required. The bodies of all our open-end blind rivets are fabricated by cold-heading, offering superior strength and excellent appearance.

Rivets can be used in numerous applications with low load bearing applications. Rivets are handy where access at the back of the work piece is restricted or not accessible.

The standard head style is dome which is suitable for most applications, large flange rivets are good for riveting thin or softer materials such as plastic, timber etc to a rigid backing,such as fastening softer materials (wood or plastic, for example) to metal.

A countersunk rivet is used primarily on metal surfaces where a flush appearance is required.

1. What is a round head blind rivet?

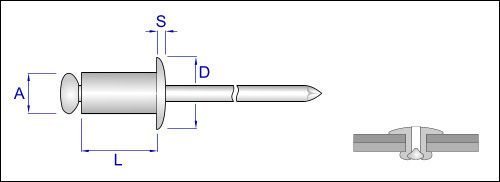

Dome head blind rivets are fasteners designed to join or connect two or more materials, such as metal or plastic, together. They consist of a cylindrical shaft with a solid spindle inside. The mandrel acts as a breaking point, breaking when installed to create a strong joint. Round head blind rivets are unique in that they have a dome shape on one end, providing a smooth and aesthetically pleasing surface to the joint.

2. Unparalleled strength and load-bearing capacity

The domed head design of these rivets contributes to their superior strength and load-bearing capacity. The dome distributes the load evenly over the rivet, preventing it from digging into softer materials and ensuring a secure grip. This property makes them ideal for applications requiring long-lasting tensile and shear strength, providing excellent resistance to vibration and other external forces.

3. Application versatility

Dome head blind rivets are widely used in various industries due to their versatility. These rivets are commonly used in automotive manufacturing to secure body panels, interior trim, and structural components. In the aerospace industry, dome head blind rivets are critical for joining aircraft frames, fuselage panels and landing gear assemblies. They also play an important role in construction, fixing metal roofing and cladding, and general fabrication and repair work.

4. Easy to install and efficient

One of the significant advantages of dome head blind rivets is their ease of installation. The blind rivet installation process requires access to only one side of the joint, making it ideal for situations where access to the backside is not possible. These fasteners can be easily installed using simple tools like a blind or hand rivet gun, saving time and effort compared to other joining methods.

5. Enhance aesthetics and corrosion resistance

In addition to their superior strength and ease of installation, dome head blind rivets help improve the aesthetics of the finished product. The domed head provides a flush surface on the joint surface, eliminating any protruding or sharp edges. In addition, they are available in a variety of materials, including aluminum and stainless steel, with excellent corrosion resistance, further extending the life of the joint.

Conclusion

In summary, round head blind rivets are superior fasteners that offer unparalleled strength, versatility and ease of installation. With their ability to withstand heavy loads, they have become an integral part of numerous industries, ensuring safe and durable connections.